Uyazi ukuba loluphi uhlobo lwemigangatho ekufunekaIzikhonkwane zezibane zesitalato ze-LEDdibana? Umenzi wezibane zesitalato uTIANXIANG uza kukusa ukuze akuxelele.

1. Ipleyiti yeflange yenziwe ngokusika kweplasma, inemida egudileyo, akukho zibharha, imbonakalo entle, kunye neendawo ezichanekileyo zemingxuma.

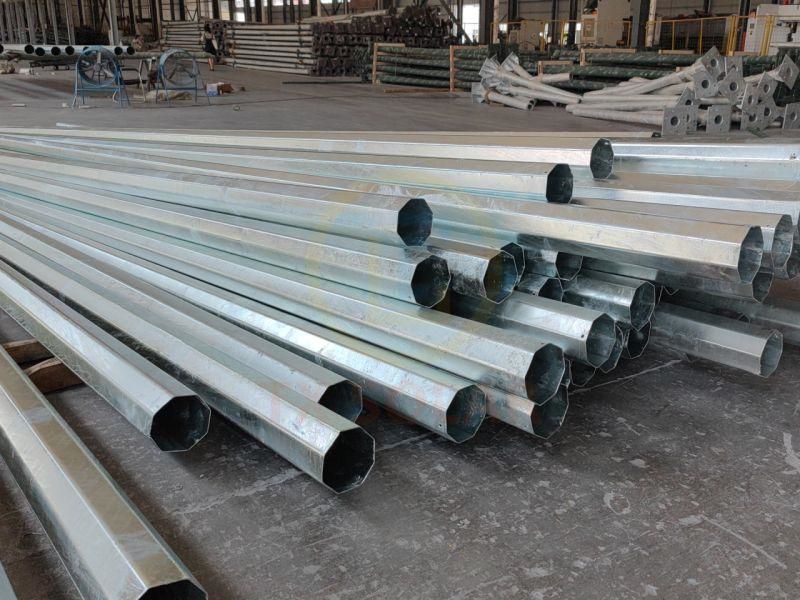

2. Ingaphakathi nangaphandle kwepali yokukhanya yesitalato ye-LED kufuneka iphathwe nge-hot-dip galvanized yangaphakathi nangaphandle yomphezulu ochasene nokugqwala kunye nezinye iinkqubo. Umaleko we-galvanized akufuneki ube mkhulu kakhulu, kwaye umphezulu awunamahluko emibala kunye noburhabaxa. Inkqubo yonyango lwe-anti-corrosion engentla kufuneka ihlangabezane nemigangatho yesizwe ehambelanayo. Ngexesha lenkqubo yokwakha, ingxelo yovavanyo lwe-anti-corrosion kunye nengxelo yokuhlolwa komgangatho wepali yokukhanya kufuneka inikwe.

3. Umphezulu wepali yesibane sesitalato se-LED kufuneka utshizwe ngombala, kwaye umbala kufuneka uhlangabezane neemfuno zomnini. Ipeyinti yodidi oluphezulu kufuneka isetyenziswe ekutshizeni ngeplastiki, kwaye umbala uxhomekeke kumfanekiso wesiphumo. Ubukhulu beplastiki etshiziweyo bungaphantsi kwe-100 microns.

4. Iipali zokukhanya zesitalato ze-LED kufuneka zibalwe kwaye zilawulwe ngokweemfuno zamandla ngokwesantya somoya kunye namandla achazwe kumgangatho wesizwe. Ngexesha lenkqubo yokwakha, kufuneka kubonelelwe ngeenkcazo zezinto kunye nokubalwa kwamandla anxulumene neepali zokukhanya. Kwiipali zokukhanya ezidityaniswe ngentsimbi yentsimbi, umenzi wekontraka kufuneka acoce iindawo zokudibanisa iintambo ngaphambi kokuba adibanise aze enze imingxunya ngokwemigaqo.

5. Ucango lwesandla olunepali yesibane sesitalato se-LED, uyilo locango lwesandla olunepali kufuneka lube luhle kwaye lube nobubele. Iingcango zisikwe ngeplasma. Ucango lombane kufuneka ludityaniswe nomzimba wentonga, kwaye amandla olwakhiwo kufuneka abe mahle. Ngendawo efanelekileyo yokusebenza, kukho izixhobo zokufakelwa kombane ngaphakathi kocango. Umsantsa phakathi kocango nepali akufuneki udlule kwi-millimeter enye, kwaye unamandla okungena kwamanzi. Unenkqubo ekhethekileyo yokubopha kwaye unamandla okukhusela ubusela. Ucango lombane kufuneka lube nokutshintshana okuphezulu.

6. Ukufakelwa kweepali zokukhanya zesitalato ze-LED kufuneka kuhambelane nemigaqo efanelekileyo yofakelo lwesizwe kunye nemigaqo yokhuseleko. Ngaphambi kokuba kufakwe ipali yokukhanya, izixhobo ezifanelekileyo zokuphakamisa kufuneka zikhethwe ngokweembalo zokuphakama, ubunzima, kunye neemeko zendawo yepali yokukhanya, kunye nendawo yokuphakamisa, indlela yokufuduka kunye nokulungisa kufuneka ixelwe kwinjineli yokujonga ukuze ivunywe; xa kufakwe ipali yokukhanya, izixhobo kufuneka zixhotyiswe ngeendlela ezimbini ezithe nkqo omnye komnye. Jonga kwaye ulungise ukuqinisekisa ukuba ipali yokukhanya ikwindawo echanekileyo kwaye ipali imile nkqo.

7. Xa ipali yesibane sesitalato se-LED iqhagamshelwe ngeebholiti, intonga yesikrufu kufuneka ijonge ngqo kumphezulu wokungena, akufuneki kubekho msantsa phakathi kwentloko yesikrufu kunye nenxalenye, kwaye akufuneki kubekho iiwashers ezingaphezulu kwezi-2 kwicala ngalinye. Emva kokuba iibholiti ziqinisiwe, ubude beenati eziveziweyo akufuneki bube ngaphantsi kwepitch ezimbini.

8. Emva kokuba ipali yesibane sesitalato se-LED ifakwe yaza yalungiswa, umenzi-kontrakta kufuneka ngoko nangoko enze i-backfilling kunye ne-compaction, kwaye i-backfilling kunye ne-compaction kufuneka zihambelane nemigaqo efanelekileyo.

9. Ukufakelwa kombhobho wokukhupha umbane wepali yesibane sesitalato se-LED kuya kuhambelana nemizobo kunye neenkcukacha ezifanelekileyo.

10. Ukuhlolwa kokuma kwepali yezibane zesitalato ze-LED: Emva kokuba ipali yezibane ime nkqo, sebenzisa i-theodolite ukujonga ukuma phakathi kwepali kunye nethe tye.

Le ingentla yimigangatho ekufuneka ihlangabezane neepali zezibane zesitalato ze-LED. Ukuba unomdla kwizibane zesitalato ze-LED, wamkelekile ukuqhagamshelana nomenzi wezibane zesitalato uTIANXIANG ukuzeFunda ngokugqithisileyo.

Ixesha lokuthumela: Agasti-09-2023